+1 234 567 8910

Top 6 Advantages of Using a Bulk Bag Discharger

Optimizing processes is paramount for efficiency in the dynamic landscape of material handling. One crucial player in this realm is the Bulk Bag Discharger. This hero makes unloading materials easier and has many benefits for different industries. Businesses in Pune are using Bin Activator Pune and Circular Vibratory Screens. These solutions have many advantages. Here are six reasons why using a Bulk Bag Discharger can improve your material handling operations.

1. Increased Operational Efficiency

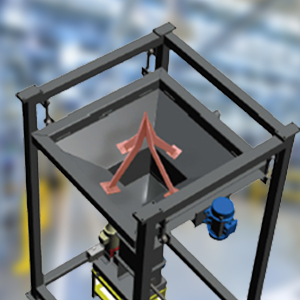

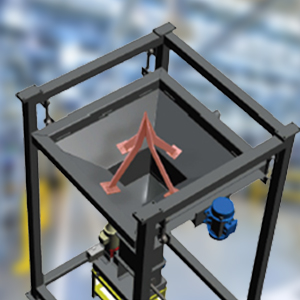

Lifting and pouring heavy bags by hand wastes worker hours and slows down production. The frames of Bulk Bag Unloaders have an electric hoist. The hoist is mounted on the ceiling. It allows easy lifting of bags up to 2 tons. This helps to avoid back strain.

Swift Bulk Bag Unloaders loading saves time. It creates a smoother material flow. It helps keep up with processing demand. There is no downtime or output lags because of bag handling bottlenecks.

2. Reduced Wastage/Improved Yield

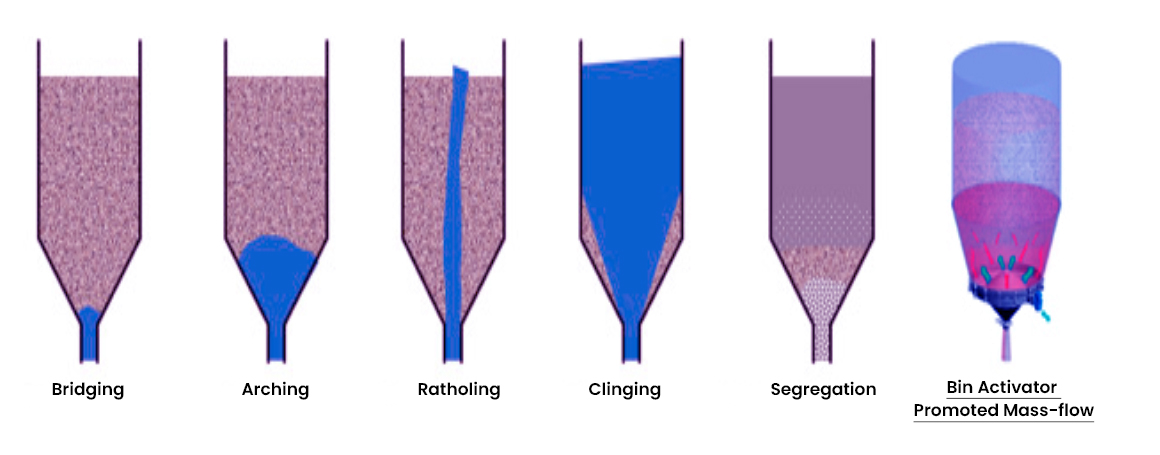

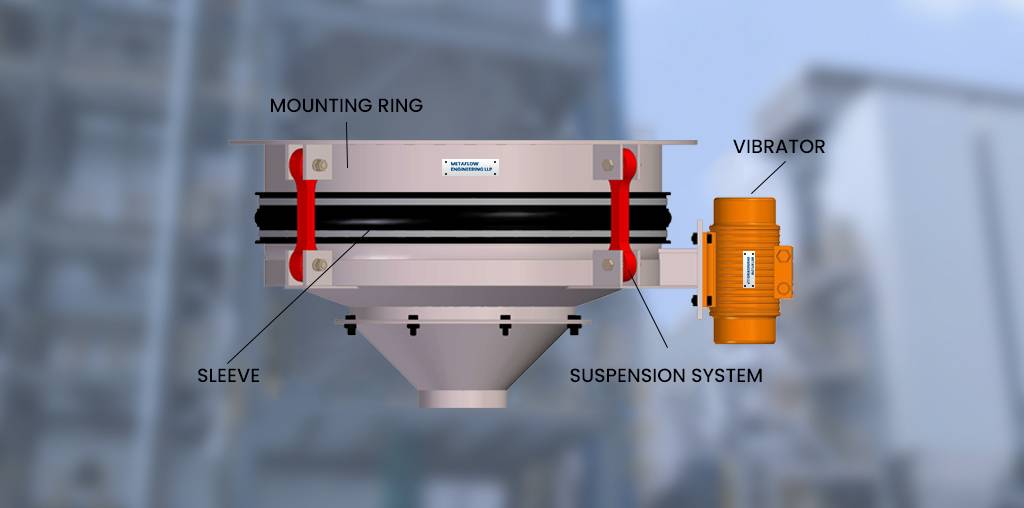

Dumping bulk bags without support causes spills and losses. Dischargers hold bags above vessels. They regulate material discharge with a slide gate.

This material flow prevents spills. It empties bags completely. It uses vibration motors. No product is left inside. Manual draining can leave residue. It yields better and has no waste.

3. Enhanced Operational Safety

Manually lifting heavy bags brings injury risks from pulls, drops, and trips/falls. However, automated Bulk Bag Unloader Pune removes direct worker contact, optimizing floor safety. State-of-the-art designs even have tear detection systems preventing bag ruptures through sensors detecting abnormal discharge rates.

You also avoid exposure to fine powders as enclosed designs prevent dusting, unlike makeshift cut-open pouring with billowing particle clouds!

4. Customizable Configurations

Metaflow Engineering, a leading Bulk Bag Discharger manufacturer, offers customizable frames, bag lifts, hoppers, and de-stuffing modules. These options can be transportable or mezzanine-mounted. This allows for a perfect fit to the facility's height, the required flow rates, and the feeding positions.

Specific design elements can help with trickier application needs. For example, they can handle high fat content powders that tend to stick.

5. Hygienic Construction

Pharmaceutical and food applications demand the utmost hygienic material handling to avoid batch contamination. Discharger contact parts made from stainless steel or easy-clean plastics cater to such sensitive sectors. Smooth polished surfaces prevent particle accumulation and ease washdowns.

Certain models even have inflatable tube seals ensuring complete dust retention - vital for sterile processes like dairy or biopharma!

6. Validation Assistance

Reputable discharger brands provide documentation. This includes CAD drawings, functional descriptions, and equipment test procedures. The purpose is to support client validation needs. This is especially important in regulated sectors like chemicals and healthcare.

Conclusion

The advantages of integrating a Bulk Bag Discharger in material handling extend far beyond streamlined processes. From the bustling industrial landscape of Pune to global manufacturing hubs, businesses are reaping the benefits of improved efficiency, workplace safety, and cost-effectiveness. As technology continues to evolve, embracing solutions like Bulk Bag Dischargers from Metaflow Engineering becomes a choice and a necessity for those seeking to stay ahead in the competitive material handling world.

Bulk Bag Unloader Pune: Types, Features, and Selection Tips

Using Bulk bag Unloaders, powdered or granulated ingredients can be dust-free and hygienically discharged from FIBCs into processing machines. However, choosing the optimal configuration can be confusing with various unloader types available.

This guide covers key bulk bag unloader varieties, capabilities and best practices for selection:

Common Unloader Types

Selecting the optimal Bulk Bag Dischargers involves understanding the core varieties on the market and their suitability for different operational contexts. The three main types include:

1. Stationary Dischargers

Stationary unloaders have a fixed frame. They are installed next to the receiving vessel or process machine. They help with simple material flow requirements for bulk bags. The output location usually stays the same. The key features are an electric hoist for lifting bags up to 2 tons, a height-adjustable bag hanging stand, and an adjustable slide discharge gate to control flow rates.

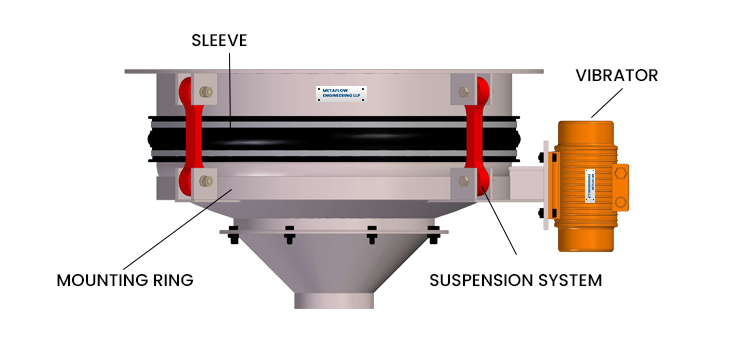

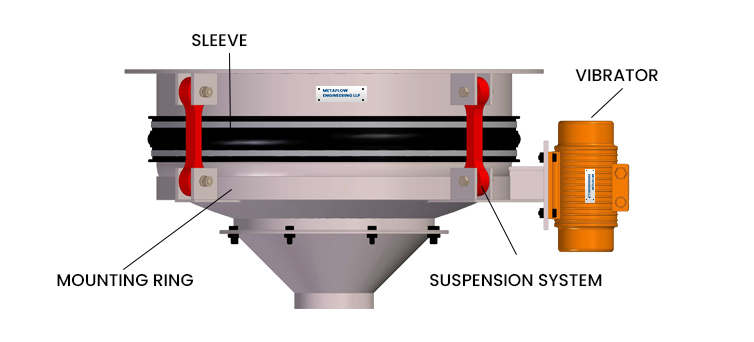

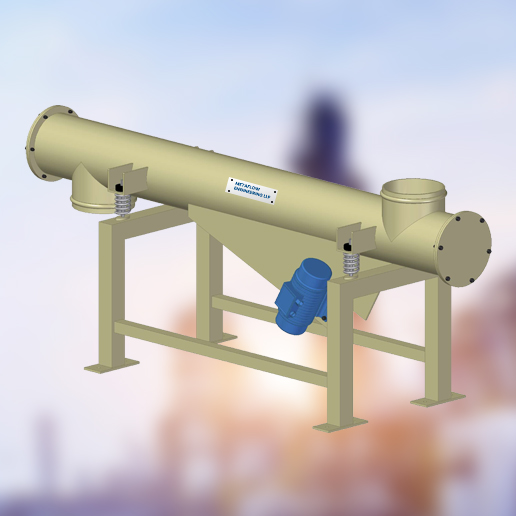

Vibrating Feeders massage systems help with tricky products. They prevent arching and rat holing. Metaflow's MEF model is a stationary discharger. It has a compact footprint and is easy to operate. It has a moderate output capacity of up to 2000lb/hr. This model is suitable for facilities with centralized feeding areas that don't need mobility.

2. Trolley Dischargers

Mounted trolley dischargers are used in plants with intermittent feeding on different machines. They help with moving materials easily. The Bulk Bag Discharger assembly has industrial casters. It helps transport bags quickly across longer distances. It goes to different feed points on a production floor. Units can be customized to match machine height and location. Ideal for facilities with different equipment layouts spread out.

3. Continuous Dischargers

In high-demand applications needing very heavy duty 20000lb+/hr bulk handling, continuous dischargers maintain non-stop material discharge. This is achieved through multiple bag stands arranged in a rotating carousel assembly...

The remainder can describe the features of continuous and carousel dischargers. But the above expands well on the details of stationary and trolley models as the two main varieties.

Key Unloader Features

While stationary, trolley and continuous dischargers represent the core varieties, models within each type offer several configurable features and accessories to match operational needs:

1. Customizable Configurations

Consult Bulk Bag Unloader Pune, like Metaflow Engineering, for fully customized unloaders instead of using off-the-shelf systems that are one-size-fits-all. Please provide details such as discharge height, electric hoist capacity for common bag weights, hopper dimensions, and mobility requirements. This will help us find the best solution to optimize process efficiency.

2. Dust Control Accessories

To prevent leaks, use more dust control accessories. These can include inflatable neck seals, glove ports, integrated rotary valves, and bag shredders. Choose the accessories based on the level of containment needed. Augmented features are important for industries like pharmaceuticals. Sterility is crucial when handling ingredients.

3. Bag Massagers

Certain ingredients prone to sedimentation, rat holing or de-mixing pose flow challenges. Here, specialized Vibrating Tube Feeders Pune massagers fitted externally promote consistent material discharge. The agitation prevents arching, tunneling or lump formation for reliable emptying of trickier products. Ideal for fine chemicals, clays, titanium dioxide and food items.

4. Safety Enhancements

Mission-critical safety can be bolstered by selecting advanced electric hoist models with braking systems...

Further sections can detail the safety mechanisms documentation for compliance and advise on aligning customized unloader builds to application needs through material testing.

Tips for Unloader Selection

First, determine your output requirements – intermittent or high volume continuous?

Factor in space availability and process layout for sizing evaluation

Consult expertise of vendors like Metaflow Engineering on product testing to pick optimal models suiting material flow properties

Prioritize certified safety-enhanced dischargers for risk mitigation

To enjoy efficient, problem-free bulk bag discharging, contact the experts at Metaflow Engineering today for reliable Pune-made equipment!

Enhancing Industrial Efficiency: The Functioning and Benefits of Vibrating Compaction Tables and Vib

Introduction

In the dynamic landscape of industrial processes, Pune has emerged as a hub for innovative solutions aimed at optimizing efficiency and productivity. This article delves into the functioning and benefits of key devices like:

Vibrating Compaction Table

Vibrating compaction tables are indispensable in manufacturing processes where settling and compacting of materials are crucial. In Pune's industrial landscape, these Vibrating compaction tables Pune find applications in molding, casting, and packaging operations.

Circular Vibratory Screen and Vibrating Screen

Circular vibratory screens and vibrating screens are essential components in the separation and classification of materials. The circular vibratory screen operates by imparting a gyratory motion to the material, facilitating efficient separation based on size and shape. Vibrating screen Pune, on the other hand, use linear motion for the same purpose.

Vibratory Trough

Vibratory troughs are instrumental in conveying bulk materials seamlessly within industrial setups. In Pune's manufacturing units, these vibrating trough pune are employed in material handling systems, facilitating the smooth transfer of goods from one point to another.

Bin Activators

Bin activators play a critical role in silo discharging systems, preventing material clogging and ensuring a continuous flow. In Pune, where storage and handling of bulk materials are integral to various industries, bin activators pune are employed to maintain the flow of materials from storage bins.

Vibrating Feeders

Vibrating feeders are the lifeline of many manufacturing processes in Pune, especially in industries that deal with precise feeding and dosing of materials. The use of vibrating feeders pune not only optimizes production but also minimizes waste, contributing to cost-effectiveness.

Vibrating Table

Vibrating tables find diverse applications in Pune's manufacturing landscape, from concrete casting to compaction of bulk materials. These vibrating table pune use vibration to settle and compact materials, ensuring uniformity in density.

Vibratory Screening Equipment

Vibratory screening equipment is integral to the sorting and grading processes in Pune's industries. These devices employ vibration to separate materials based on size, ensuring that only particles of the desired specifications proceed further in the production line. In industries dealing with aggregates, minerals, or even food products, vibratory screening equipment enhances the quality and uniformity of the final output while minimizing wastage.

Electromagnetic Vibratory Feeder and Vibratory Powder Feeder

Precision in material feeding is paramount in many industrial processes in Pune. Electromagnetic vibratory feeders and vibratory powder feeders are designed to handle this task with finesse. The electromagnetic vibratory feeder uses magnetic fields to drive materials forward with precise control, while Vibratory Powder Feeder are specifically designed for handling powders and granular materials. These devices contribute to the accuracy of material feeding, reducing errors and enhancing the overall efficiency of manufacturing processes.

Vibro Sifter

In industries where the separation of particles of different sizes is crucial, the vibro sifter comes into play. Pune's pharmaceutical and food processing industries, in particular, benefit from the precise particle separation capabilities of vibro sifters.

Bin Activator

Bin activator ranging from mining to chemical processing. Their ability to prevent material blockages in storage bins ensures a continuous and controlled flow of materials, minimizing disruptions in production processes.

Conclusion

In Pune's industrial landscape, the adoption of vibrating compaction tables and various vibratory equipment has become synonymous with progress and efficiency.

Comprehensive Solutions for Material Handling and Processing

In the dynamic industrial landscape, where precision and efficiency are paramount, the adoption of advanced material handling equipment has become synonymous with operational excellence.

Bulk Bag Discharger: A Comprehensive Guide

A bulk bag discharger, also known as a bulk bag unloader or big bag discharger.These bags typically store and transport large quantities of dry bulk solids such as powders, granules, or pellets. Installing a bulk bag discharger requires careful planning and execution to ensure optimal performance, safety, and efficiency.

Bin Activator: Promoting Flow and Preventing Blockages

Bin Activators Pune industries serve a critical role in promoting material flow from storage bins. These devices prevent material blockages, ensuring a continuous and consistent supply of materials downstream. The result is improved production efficiency and minimized disruptions.

Bulk Bag Unloaders: Streamlining Unloading Processes

Bulk Bag Unloaders are engineered for efficiency in unloading bulk bags. By providing a systematic and controlled discharge, they contribute to smoother operations, reducing manual handling efforts and optimizing material transfer processes.

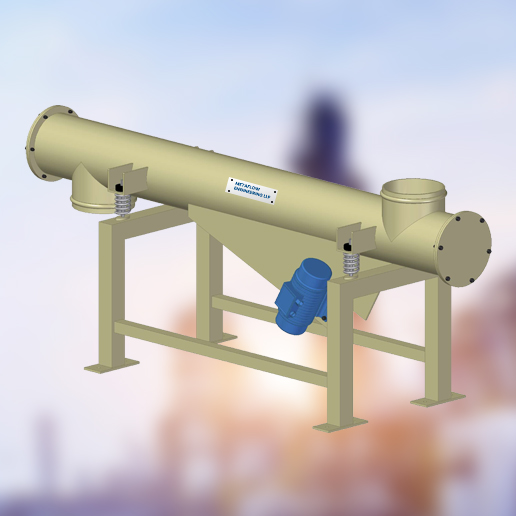

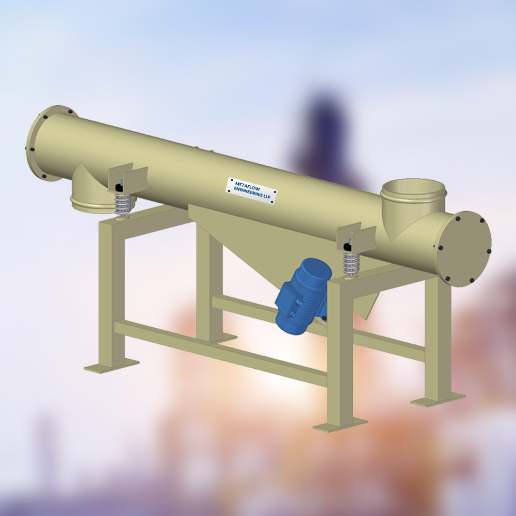

Screw Bins: Controlled Material Conveyance

Screw Bins play a crucial role in material conveying systems, ensuring the controlled transport of materials. Their screw mechanisms enable a precise and steady flow, minimizing waste and enhancing the reliability of material conveyance.

Vibrating Feeders: Precision in Material Conveyance

Vibrating Feeders offer versatile solutions for conveying bulk materials with precision. In Pune industries, these feeders ensure a consistent and controlled material supply, reducing the risk of overfeeding or underfeeding and improving overall process efficiency.

Vibrating Screens: Quality Material Classification

Vibrating Screens are instrumental in the screening process, classifying materials based on size. By ensuring accurate separation, these screens contribute to product quality and adherence to industry standards.

Tube Vibrating Feeders: Gentle Handling for Fragile Materials

Tube Vibrating Feeders are specifically designed for applications requiring gentle material handling, making them ideal for fragile materials. These feeders minimize material degradation, preserving the integrity of the conveyed materials.

Compaction Tables: Optimizing Material Density

Compaction Tables play a vital role in settling and compacting materials, optimizing their density. By improving the packing of materials, these Compaction tables contribute to efficient packaging and transportation processes, ultimately reducing costs.

Circular Screens and Circular Gyratory Screens: Precision in Material Separation

Circular Screens and Circular Gyratory Screens are essential for precise material separation and classification. Their design ensures accuracy in separating materials of different sizes, improving overall production efficiency.

Vibrating Tube Feeders: Reliability in Material Feeding

Vibrating Tube Feeders Pune offer reliable solutions for material feeding in various industrial applications. Their robust design ensures a consistent and controlled flow of materials, minimizing disruptions and enhancing overall operational reliability.

Rectangular Vibrating Screen: Tailored Solutions for Specific Applications

Rectangular Vibrating Screens are tailored for applications requiring a rectangular screening surface. In Pune, industries benefit from their versatility and efficiency in material separation, providing tailored solutions for specific production needs.

Bulk Bag Unloader: Efficient Bulk Bag Handling

Bulk Bag Unloaders Pune are pivotal in handling bulk bags efficiently. By providing a systematic and controlled unloading process, these unloaders contribute to a reduction in manual labor, ensuring worker safety and streamlining material handling operations.

Conclusion:

The adoption of these technologies not only enhance material handling processes but also contribute to minimizing waste, improving worker safety, and ultimately positioning Pune industries at the forefront of innovation and productivity.

Maximizing Material Transport Efficiency: The Benefits of Vibration Machines in Bulk Solid Handling

In diverse sectors encompassing agriculture, construction, mining, and manufacturing, effective management of bulk solids is of paramount importance. The continuous, unhindered flow and transfer of materials, whether they are aggregates, powders, grains, or other bulk solids, form the cornerstone of operational success. Vibration machines have emerged as indispensable instruments, significantly enhancing the efficiency of these processes while bestowing a multitude of advantages that have revolutionized the landscape of bulk solid handling.

Enhanced Material Flow and Uniformity

Vibration machines, often referred to as vibratory feeders or conveyors, harness mechanical vibrations to expedite the transit of bulk materials. Circular Gyratory Screens are the best. Typically, these machines comprise a trough or tube affixed to springs or hinged links, which experience excitation via an eccentric drive mechanism. This generates vibrations that enable the precise and consistent movement of materials along the trough.

The mechanism of vibration equipment operates as follows:

Stimulation: The eccentric drive mechanism, frequently powered by an electric motor featuring an imbalanced weight, generates vibrations within the trough. Vibrating Tube Feeders Pune are used widely.

Material Flow: These vibrations encourage the bulk solids within the trough to move in a specified direction, whether forward or upward, contingent upon the machinery's design. Many people prefer Rectangular Vibrating Screen Pune.

Fine-tuning: Vibration machines can be adjusted to regulate the flow rate, ensuring materials traverse at the desired velocity and capacity. Bulk Bag Unloader Pune is actually fantastic.

This fundamental operational framework ensures the seamless and uniform progression of materials, effectively circumventing issues such as bridging, ratholing, or flooding. Vibrating Compaction Table Pune has been excellent. The ultimate outcome is an optimized material flow and uniformity, which stand as pivotal components of efficient bulk solid handling.

Heightened Efficiency and Productivity

The integration of vibration machines into bulk solid handling proffers substantial time-saving benefits. You can find Circular Vibratory Screen easily. The manual creation of invoices can be a labor-intensive process, entailing the formulation of templates, data entry, and the rigorous verification of accuracy. In stark contrast, the incorporation of vibration machinery streamlines these operations by automating these tasks. Bin Activators Pune are outstanding.

These machines feature pre-defined templates, allowing for the automated calculation of totals, and also provide the flexibility to accurately include taxes and discounts. You can find Vibrating Table Pune online. This automation substantially curtails the time invested in generating professional invoices. The time economized can then be redeployed toward more productive core business activities, ultimately culminating in heightened productivity and a commensurate elevation of profitability.

Customization and Branding Opportunities

Online tools for generating invoices offer a high degree of customization. Users are afforded the liberty to personalize their invoices to align with their brand identity by incorporating company logos, individualized details, and selecting layouts that mirror the essence of their business. People generally choose Electromagnetic Vibratory Feeder. This not only amplifies the professionalism of the invoices but also reinforces consistency in brand representation. Clients are more inclined to place their trust in and recollect businesses that present refined, branded invoices.

The utilization of vibration machines in the processes of bulk solid handling has evolved into an indispensable practice for industries reliant upon the seamless conveyance of bulk materials. People even prefer Vibratory Powder Feeder. Their capacity to ensure a consistent material flow, mitigate the risk of errors, and advance operational efficiency underscores their significance.

Improving Efficiency in the Handling of Bulk Solids: The Significance of Vibration Machinery

In numerous sectors, such as agriculture, construction, mining, and manufacturing, efficient management of bulk solids plays a pivotal role. These industries heavily depend on the uninterrupted flow and conveyance of various materials, ranging from aggregates, powders, to grains, and other forms of bulk solids. Vibration machinery has surfaced as invaluable tools in optimizing the efficiency of these operations.

The Fundamentals of Vibration Apparatus

Vibration apparatus, also recognized as vibratory feeders or conveyors, constitute mechanical contrivances engineered to displace bulk materials through the utilization of vibrations. Typically, these machines consist of a trough or tube affixed to springs or hinged links, which are stimulated by an eccentric drive system. Bulk Bag Discharger is used widely. These resultant vibrations facilitate the orderly progression of materials along the trough.

Initiation: The eccentric drive mechanism, typically encompassing an electric motor featuring an unbalanced weight, initiates vibrations within the trough. Bin Activator Pune has outstanding results.

Material Propulsion: The vibrations induce the bulk solids within the trough to advance in a particular direction, contingent on the machinery's design. Bulk Bag Unloaders are the best.

Customization: Vibration machinery can be adapted to regulate the flow rate, ensuring materials move at the desired speed and capacity. You can find Screw Bins easily.

The Merits of Vibration Machinery in Bulk Solid Handling

The utilization of vibration machinery extends several advantages to the handling of bulk solids:

Uniform Conveyance: Vibration machinery guarantees a consistent and uniform flow of materials, mitigating issues like bridging, ratholing, or flooding. Vibrating Feeders are affordable.

Enhanced Productivity: By sustaining a steady material flow, these machines augment operational efficiency, thus diminishing downtime and elevating productivity levels. Vibrating Screens have the finest quality.

Delicate Handling: Vibration conveyors are acclaimed for their gentle material handling, significantly minimizing any degradation or damage to delicate materials. Tube Vibrating Feeders are pretty fantastic.

Personalization: Vibration machinery can be tailored to cater to specific material characteristics and process requisites, rendering them versatile across diverse industries. Compaction Tables have reasonable prices.

Applications in Myriad Sectors

Vibration machinery finds application across a wide spectrum of industries. Let's delve into some illustrative examples:

Agriculture: Vibration conveyors find utility in the transportation of grains, seeds, and cereals, ensuring a consistent supply for sorting, processing, and packaging.

Mining: In the mining sector, these machines facilitate the conveyance of ores, aggregates, and minerals across different processing stages.

Manufacturing: Vibration conveyors are engaged in the movement and feed of assorted materials in manufacturing operations, thereby elevating production efficiency.

Food Processing: These machines gently oversee the handling of food products, such as nuts, coffee beans, and candies, preserving their structural integrity.

The Future of Vibration Machinery

As industries continue to evolve, the role of vibration machinery in bulk solid handling is poised for expansion. Advanced control systems, heightened energy efficiency, and the proliferation of automation are poised to play a significant role in shaping the trajectory of these machines. Their contribution to sustainable and efficient material handling processes is monumental, making them an indispensable component of various industrial operations.

To conclude, vibration machinery has evolved into indispensable tools, enhancing the efficient management of bulk solids across diverse industries. Their capacity to ensure a uniform material flow, mitigate material degradation, and bolster operational efficiency underlines their significance.

Is a Bulk Bag Discharger Right for Your Business?

In today's fast-paced manufacturing and production environment, efficiency is the name of the game. From Bin Activator Pune to Vibrating Feeders, companies constantly seek equipment that speeds up the process and cuts costs. But have you ever considered whether a Bulk Bag Discharger is a good fit for your business? This might seem like an arcane piece of equipment, but the benefits can be astronomical.

From reducing manual labour to ensuring a smooth material flow, this machine might just be the piece of the puzzle you didn't know was missing. Read on as we delve into what a Bulk Bag Discharger does, its benefits, and how to determine if it fits your operation correctly.

What is a Bulk Bag Discharger?

Simply put, a Bulk Bag Discharger is a piece of equipment designed to efficiently unload bulk bags (also known as FIBC or "Flexible Intermediate Bulk Containers"). This machine carefully holds the bag and then discharges its contents—like grains, powders, or pellets—into a production line or storage unit. This could be especially beneficial if your business deals with large quantities of raw materials.

The Benefits: More than Just Unloading

Streamlined Material Handling

One of the first things that strikes you about a Bulk Bag Discharger is its impact on material handling. With its advanced design, it significantly cuts down the manual labor required for unloading large bags. This speeds up the process and ensures that the contents are emptied into your Screw Bins or other storage units with minimal effort.

Waste Minimization

We all know that waste equals loss in any business. When you employ a Bulk Bag Discharger, you reduce waste significantly. The precise unloading mechanism ensures that the materials are transferred directly where needed, whether a Vibratory Powder Feeder or a Vibro Sifter, minimizing spillage and waste.

Cost-Effectiveness

Believe it or not, investing in a Bulk Bag Discharger can be incredibly cost-effective in the long run. While the initial outlay may seem steep, the speed and efficiency gains quickly justify the expense. The machine can easily integrate with your existing Vibratory Screening Equipment or Vibrating Feeders Pune, making it a versatile addition that boosts overall productivity.

Is It Right for Your Business?

This machine can be a game-changer if your company often deals with bulk materials. However, there are a few factors you should consider:

Volume

The investment makes sense if you're handling large quantities of materials. Other equipment like Vibrating Table Pune may be more suitable for smaller operations.

Type of Material

Not all dischargers suit all materials. Choose one that aligns with what you’re producing or handling.

Space

Ensure you have enough room in your facility for this equipment.

Conclusion

Investing in specialized equipment is not a decision to be made lightly. Yet, a Bulk Bag Discharger can be an incredible addition to your workflow, dramatically increasing efficiency, safety, and versatility. If you're looking for quality industrial equipment, ranging from Bin Activator Pune to Compaction Tables, there's one place to find it all—Metaflow Engineering. Browse our extensive product catalog today and take the first step in optimizing your business operations.

5 Features to Look for in Screw Bins

When it comes to handling and storing bulk materials, every component in your setup matters. From Bulk Bag Unloaders to Vibrating Feeders, the efficiency of your operation can hinge on a single piece of equipment. Among these essentials, one often-overlooked item is the Screw Bin. While they may seem straightforward, these bins are far more than simple storage containers. They are critical in managing flow, reducing waste, and maintaining quality. With various types of bins available, it's crucial to understand what to look for. Today, we'll discuss the top 5 features you should watch when choosing Screw Bins for your facility.

1. Material Durability

The first and foremost aspect to consider is the durability of the material. Screw Bins often deal with abrasive or corrosive substances. Opt for bins made from materials that can withstand the type of products you'll store. It will not only prolong the life of your bins but also ensure the safety and quality of your stored material.

2. Capacity

The bin’s capacity needs to align with your production or storage needs. It's inefficient to pick a small bin for a high-volume operation, just like having a large bin for minimal storage is a waste. When assessing capacity, factor in how well the bins work with other equipment like Tube Vibrating Feeders or Vibrating Screens to maintain a seamless flow.

3. Flow Mechanism

While traditional bins rely on gravity to move materials, Screw Bins use screw conveyors for better flow control. Ensure the flow mechanism integrates seamlessly with your existing setup, such as Bulk Bag Discharger or Vibro Sifter, for efficient material handling.

4. Adaptability

In a dynamic manufacturing environment, adaptability is key. Check if the Screw Bin is versatile enough to work with different types of machinery. If your operations involve Compaction Tables or Vibrating Compaction Table Pune, your bins should be compatible with these. Versatility can save you from headaches when you upgrade or change your existing machinery.

5. Ease of Cleaning

Last, consider how easy it is to clean the bins. You don't want to spend hours cleaning when you switch materials or do regular maintenance. The design should allow for easy removal of leftover materials. It should also be compatible with cleaning protocols. It is especially important if you are in a sector that mandates strict hygiene, like food or pharmaceuticals.

Conclusion

Screw Bins are important in material handling setups. They may not be flashy, but they are essential. Making the right choice can enhance productivity. Making the right choice can streamline operations. The right choice can enhance productivity and streamline operations. The right choice can enhance productivity and streamline operations. Remember these five features when you're ready to upgrade or invest in new Screw Bins. It will ensure you make an informed decision.

And if you're looking for a one-stop shop for all your industrial equipment needs, from Bin Activators Pune to Circular Screens, look no further than Metaflow Engineering. Our expert team is always on hand to guide you in selecting the best solutions for your requirements. Visit us today to take your operations to the next level.c

The Way Vibration Machines Change the Game in Bulk Solids Handling.

When the timely and effective movement and processing of raw materials is of the utmost importance, as it is in the agricultural and mining sectors, bulk solids handling is an indispensable procedure. The introduction of vibration machines has been a game-changer in this industry because of the many advantages they bring to the process of handling bulk materials.

Increased Material Flow

Material flow may be greatly enhanced by utilizing Rectangular Vibrating Screen Pune, which is one of their key benefits in bulk solids handling. Problems with caking, arching, or ratholing in the bulk material might prevent it from moving freely through hoppers, chutes, and conveyors. Controlled vibrations used by vibration machines solve these problems and maintain an even and effective flow. This eliminates wait times and speeds up production.

Lessening of Material Sorting

When moving or storing bulk materials, material segregation is a typical problem since particles of different sizes and densities tend to separate. Vibrating Compaction Table Pune is used to lessen the impact of this issue since they facilitate particle mixing and stop material separation. This guarantees that the end product's composition is stable, which ultimately improves the quality of the final product. Bulk Bag Unloader Pune is indeed outstanding.

Efficacy is Improved

Manufacturing relies heavily on efficient processes. The efficiency of operations involving the processing of bulk materials is greatly improved by the use of Circular Vibratory Screen. These devices improve output by minimizing the time it takes to transport materials from one place to another. Vibrating Screen Pune is an economical option due to their increased productivity and low impact on the environment.

The Extended Use of Existing Equipment

Due to the abrasive character of many materials, bulk solids handling equipment is constantly being put through its paces. Bin Activators Pune are the best. Hopper, chute, and conveyor systems can all benefit from being vibrated to increase their useful life. By decreasing the amount of friction and adhesion forces between the material and equipment surfaces, these devices lessen the wear and tear that abrasive materials have on the machinery and, in turn, save money on repairs.

Accurately Dispensing Contents

Vibrating Feeders Pune excel in sectors such as pharmaceuticals and food processing where accurate dosing of ingredients is essential. Vibrating Table Pune is the best. In order to guarantee that operations are up to par, these machines may be adjusted to deliver precise and constant material feeding rates. Minimizing product waste and increasing overall process control are two additional benefits of having tight control over the flow of materials.

Adaptability

Vibratory Screening Equipment may be used in a wide range of industries and can process a wide variety of materials. They are versatile because they can process a broad variety of bulk materials, from extremely fine powders to large granules. Electromagnetic Vibratory Feeder can be modified to suit a variety of purposes, including the processing of agricultural goods, chemicals, minerals, and culinary components.

Bulk solids handling has entered a new era of efficiency and efficacy thanks to the advent of vibration machines. Vibratory Powder Feeder is vital in many fields thanks to their capacity to improve material flow, lessen segregation, boost productivity, lengthen the life of equipment, feed materials precisely, give flexibility, and save resources.

Bulk-Stuff-Handling Vibration Machines: Cutting-Edge Technology

From agriculture to the pharmaceutical industry, bulk solids handling is essential. Efficient transportation and processing of these resources are critical for productivity and cost-effectiveness. Machines that use vibration to increase material flow, prolong the life of equipment, and reduce risks have become vital in the field of bulk solids handling.

Introduction to Vibrational Equipment

Mechanical devices meant to induce regulated vibrations into bulk solid materials are called vibration machines. These machines are also known as vibratory feeders or conveyors. Oscillations are produced in these devices by a variety of methods, including electromagnetic drives, rotary motors, and pneumatic systems. Bulk Bag Discharger is actually good. Their basic function is to facilitate conveyance by imparting energy into the material and setting it in motion along a predetermined path.

Enhanced Flow of Materials

Enhanced material flow is a major benefit of employing vibration machines for bulk solids handling. Compaction and arching of materials are two common causes of manufacturing delays in various fields. Bin Activator Pune has the finest results. Machines that use vibration to agitate the material, break up clumps, and maintain a steady flow rate can help eliminate these problems. This improves overall process efficiency and also minimizes downtime.

Accurate Measurement of Resources

Accurate material metering is crucial for quality control and process consistency in many bulk solids handling applications. Machines that use vibration can be programmed to produce a specific output in a given time period. Bulk Bag Unloaders are used widely. Pharmaceutical and food processing sectors, which require accurate dosing, rely on vibration machines because of the difficulty of achieving this degree of accuracy with traditional gravity-based methods. You can find Screw Bins easily.

Adaptability and Modularity

Vibration machines may be modified to meet the needs of a wide range of sectors and materials. Operators can optimize equipment performance by adjusting vibration frequency, amplitude, and angle. Vibrating Feeders are actually fantastic. In addition, these machines are flexible instruments in the field of bulk solids handling since they can process a broad variety of bulk materials, from fine powders to coarse granules. Vibrating Screens can be found easily.

Efficient Use of Energy

Tube Vibrating Feeders are frequently more efficient in reducing energy use when dealing with bulk materials. They can save a significant amount of energy for manufacturing processes since they need less electricity to transfer materials over the same distance. Operators may further improve energy usage thanks to adjustable vibration intensity and frequency.

Concerns About Security

Although there are many uses for Compaction Tables, they must be used with care to avoid injury. To ensure the equipment is used safely and effectively, regular training and servicing are essential. Workers need to be protected from risks such as moving components and vibrations, hence guarding and interlocking systems are necessary.

Improved material flow, increased equipment lifespan, precise material metering, adaptability, energy efficiency, and greater safety have made vibration machines vital in bulk solids handling. Circular Screens are indeed the best. Their flexibility and versatility make them invaluable in fields as diverse as agriculture and medicine. The efficiency and efficacy of Vibrating Tube Feeders Pune is expected to increase as technology permits further development of vibration machines. These devices are anticipated to play an increasingly important part in the future of bulk solids handling as we move toward a more efficient and cost-effective environment. Circular Gyratory Screens has been pretty good.

The Impact of Vibration Machines on Bulk Solids Handling.

The mining, agricultural, pharmaceutical, and food processing sectors all rely heavily on the process of bulk solids handling. Maintaining smooth traffic of massive volumes of materials is crucial for maximum output. Vibration machines are one piece of technology that has significantly altered the handling of bulk materials. These clever tools employ vibrations to improve material flow, break up obstructions, and simplify processes. The advantages of vibration machines and their effects on industrial operations will be discussed in this article.

Recognizing Vibration Equipment

Bulk Bag Discharger may be moved from one site to another with the use of vibrating machines, also called vibratory feeders. These units have a trough or tube that oscillates at a predetermined frequency, therefore transferring the bulk material along its surface. The vibrations produced within the machine maintain a steady flow of materials, eliminating the problems of stagnation and obstructions that plague conventional handling techniques.

Removing Impasses and Making Connections

Vibration machines' capacity to break up bridges and obstructions is a major benefit. Bin Activator Pune is indeed the best. Bulk sediments can build in traditional systems and get compacted, causing a blockage. Bulk Bag Unloaders are used to avoid this problem by continuously stirring the material, which dissolves any obstructions and allows the flow to proceed without interruption.

Increased Productivity and Efficiency

Vibration devices greatly increase productivity and efficiency in bulk materials handling operations by preventing jams and blockages. Screw Bins are used widely. Reduced downtime and increased output are also benefits of a steady supply of raw materials. Industries that rely on the processing of huge amounts of commodities might benefit from this efficiency improvement, since it can lead to lower operational costs and higher profits.

Modularity and adaptability

Because of its versatility, Vibrating Feeders are well-suited for processing a broad variety of bulk solids. These machines can process a wide variety of materials, including tiny powders, granules, pellets, and even abrasive ones. Vibrating Screens and frequency can be tailored to the properties of a given material for optimum efficiency.

Special Care with Fragile Objects

Tube Vibrating Feeders are ideal for businesses like the food and pharmaceutical sectors where delicate materials need to be handled carefully. Materials are protected from excessive movement and degradation during transit thanks to the carefully calibrated vibrations.

Low-energy consumption and hassle-free upkeep

Vibration machines have low power requirements because of their design. Compaction Tables are also outstanding. Due to the lack of moving parts like belts, pulleys, or chains, they are low-maintenance and cost-effective in the long run.

Conclusion

Bulk solids handling has been revolutionized by vibration machines, which provide a plethora of advantages that boost productivity and simplify production. Circular Screens has the finest results. Due to their ability to prevent bottlenecks, boost productivity, and safely handle sensitive chemicals, these devices have become standard equipment in many fields. The influence of Vibrating Tube Feeders Pune on bulk solids handling and their potential to revolutionize the way industries manage materials will only grow as technology progresses and new features and capabilities are added to these machines. Rectangular Vibrating Screen Pune is preferred by many people.

Revolutionizing the bulk solids handling industry with vibrating machines and tools.

Conveying, feeding, and screening huge volumes of materials are all examples of bulk solids handling, an essential part of many different businesses. Problems with flow, obstructions, and unequal distribution have always hampered this procedure. However, these issues have been addressed because to the development of cutting-edge vibration machines and equipment, which has increased productivity, decreased downtime, and enhanced material handling procedures. In this post, we’ll look at how vibration machinery and tools may drastically improve the process of moving and storing bulk materials.

The Function of Vibration Equipment

When it comes to the safe and efficient transfer of bulk solids, Vibrating Compaction Table Pune is an indispensable tool. To help transport materials through a trough, chute, or conveyor, these machines employ mechanical vibrations to produce oscillating motions. Vibration, when used strategically, may keep difficult materials like sticky or cohesive powders flowing smoothly and without interruption. Circular Vibratory Screen is used widely.

Vibratory feeders.

Vibrating Screen Pune is essential to the process of material handling using vibration. These machines’ adaptability and efficiency have led to their widespread use across a wide range of sectors and configurations. Vibratory Trough Pune is versatile and may be adjusted to accommodate a broad variety of bulk materials, from small powders to bigger particles.

Bin Activators: Increasing Output from Storage Bins

Bin Activators Pune are useful in sectors where bulk goods are stored in bins or hoppers. The constant supply of materials for subsequent operations is ensured by these gadgets, which assist the flow of materials from storage containers by means of regulated vibrations. By removing the need for human intervention to release trapped materials, Bin Activator not just only reduce material compaction and bridging but also minimize disturbances to operations.

Vibrating conveyors

Vibrating Feeders Pune that use vibration to move bulk materials are also crucial. They facilitate the smooth movement of raw materials between different processing stages or between warehouses and factories. Consistent flow and higher-quality output are the results of the conveyor bed’s vibrating action, which assures even distribution and prevents material segregation. Vibrating Table Pune is the best.

Screeners and Separators

Screening and separation procedures are two other areas where Electromagnetic Vibratory Feeder is useful. Material may be effectively sorted by size or other properties using a vibrating screener, which allows only the desired-sized particles through. For industries including mining, agriculture, and recycling, these screeners are indispensable for quality control, safety, and material categorization. Vibratory Powder Feeder is fantastic.

Conclusion

The bulk solids handling industry has found vibration machines and equipment to be an essential tool. The advancement of various technologies, such as vibratory feeders, vibrating conveyors, material flow aids, and screening equipment, has completely altered the nature of material transport and processing. Increased output and lower costs may be attributed to their use in a variety of industries thanks to their capacity to maintain a steady stream of raw materials, reduce downtime, and increase the quality of finished goods. In the future, we may anticipate even more cutting-edge methods to improve the efficiency of bulk solids handling procedures as technology develops.

Vibrating Equipment for Maximizing Productivity and Streamlining Operations.

The application of vibration machinery has revolutionized the field of bulk solids handling. These specialized machines use vibrations to enhance productivity in a variety of sectors by facilitating the smooth movement of materials, preventing the formation of obstructions, and reducing waste. Vibration machines have established themselves as vital resources in several industries, including mining, agriculture, healthcare, and manufacturing. This piece will explore the merits, mechanics, and uses of vibration machines in the context of bulk solids handling.

Vibration machines are vital in bulk solids handling systems, where they improve material flow and avoid obstructions. Bulk Bag Discharger is indeed the best. Cohesive forces may clump granular materials like powders, grains, and aggregates, which can interrupt the flow of the item being handled. Bin Activator Pune is preferred by many people. Controlled vibrations used by vibration machines to handling equipment like hoppers, silos, and conveyors cancel out the cohesive forces. Material bridges are dismantled, flow is enhanced, and clogs are avoided thanks to the aforementioned agitation.

Increased Productivity and Efficiency Vibration machines used in the bulk solids handling industry greatly enhance productivity and productivity. Bulk Bag Unloaders are fantastic. These devices help keep production moving by preventing material buildup, clogs, and other sources of downtime. You can find Vibrating Feeders online. As a result, output improves and downtime is cut down significantly.

Variability and Personalization: There is a wide variety of bulk solids handling vibration machines available, so adjustments may be made to meet the needs of individual projects. You can even buy Tube Vibrating Feeders. Adjustments may be made to the vibrational parameters to fit a wide range of materials, flow rates, and setups. This versatility makes vibration machines useful in many different contexts, particularly those involving the processing of materials. Circular Screens are in trend now. The best vibration equipment for any given application is often provided by manufacturers that offer customized solutions based on criteria such as material qualities, system design, and process objectives.

By using vibration machines in bulk solids handling systems, significant energy savings and reduced maintenance costs may be achieved. Vibrating Tube Feeders Pune are actually outstanding. These machines use less energy because of improvements in material flow and less friction between particles and equipment surfaces. In addition, by avoiding obstructions and buildup, you may extend the life of your equipment and minimize the amount of time and money you spend on cleaning and repairs. Rectangular Vibrating Screen Pune is used widely. Companies may save money in the long run by reducing energy use and maintenance costs, which also increases process dependability.

Utilization in a Wide Range of Fields: There are many different fields where vibration devices are useful. In the mining and quarrying industries, they are used to avoid the clogging of chutes and to allow for the regulated discharge of bulk materials. You can find Bulk Bag Unloader Pune at a lot of places. Grain, seed, and fertilizer handling are all made easier with the help of vibration machines. They are used in the chemical and pharmaceutical sectors for precision dosage and mixing. Packaging, material transfer, and assembly line optimization are all made easier with the help of vibration machines in the industrial sector.

For optimum bulk solids handling, increased productivity, and uninterrupted material flow across a wide range of sectors, vibration machines have proven to be important instruments.

Exploring the benefits and uses of vibration machines for bulk solids handling.

Vibration machines have emerged as essential tools in the field of bulk solids handling, revolutionizing the way materials are transported and processed. These machines utilize controlled vibrations to enhance material flow, prevent blockages, and improve overall efficiency. From mining and construction to food processing and pharmaceuticals, the benefits and applications of vibration machines are vast and diverse. In this article, we will delve into the advantages and uses of vibration machines for bulk solids handling, highlighting their ability to increase productivity, reduce downtime, and optimize material flow.

Improved Material Flow and Prevention of Blockages: One of the primary benefits of vibration machines in bulk solids handling is their ability to improve material flow and prevent blockages. Vibrating Compaction Table Pune is actually good. The controlled vibrations applied to hoppers, silos, and conveyors help dislodge cohesive particles, eliminate arching or bridging, and promote a steady material flow. By preventing blockages and obstructions, vibration machines ensure a continuous and efficient transfer of bulk solids, reducing downtime and increasing productivity.

Enhanced Efficiency and Productivity: Vibration machines significantly enhance the efficiency and productivity of bulk solids handling operations. Circular Vibratory Screen has the finest results. By facilitating material flow and preventing blockages, these machines minimize disruptions and downtime associated with manual interventions or equipment failures. Vibrating Screen Pune is preferred by a lot of people. With smooth and uninterrupted material transfer, processes can operate at optimal speeds, resulting in increased productivity and throughput. The enhanced efficiency allows for faster loading and unloading times, improved material blending, and reduced handling costs.

Optimized Equipment and Energy Efficiency: The implementation of vibration machines in bulk solids handling offers the advantage of optimizing equipment performance and energy efficiency. Vibratory Trough Pune will always help you. By promoting material flow, these machines reduce the friction between particles and equipment surfaces, thereby requiring less power to transport materials. This leads to energy savings and reduced operational costs. Additionally, Bin Activators Pune can enhance the performance of other equipment in the handling system, such as feeders, screens, and chutes, by improving their effectiveness and reducing wear and tear.

Versatility and Adaptability: Vibrating Feeders Pune for bulk solids handling are versatile and adaptable to various industries and material types. They can be customized to suit specific application requirements, accommodating different materials, flow rates, and equipment configurations. Manufacturers of Vibratory Screening Equipment offer a range of vibration machine options, including electromagnetic, pneumatic, and mechanical systems, allowing for tailored solutions. This adaptability makes vibration machines suitable for industries such as mining, agriculture, construction, and pharmaceuticals, where they play a crucial role in material handling, blending, dosing, and packaging processes.

Reduced Maintenance and Improved Equipment Longevity: The use of vibration machines helps reduce maintenance requirements and extends the lifespan of equipment in bulk solids handling systems. Electromagnetic Vibratory Feeder has the best results. By preventing material build-up and blockages, these machines minimize the need for frequent cleaning and maintenance interventions. The reduction in maintenance tasks translates to cost savings and increased uptime. Vibro Sifter is used widely. Moreover, the improved equipment longevity ensures a more sustainable and reliable operation, minimizing the need for frequent equipment replacements. Bin Activator is indeed excellent.

Conclusion: Vibration machines have revolutionized bulk solids handling processes by improving material flow, preventing blockages, and enhancing overall efficiency and productivity in various industries.

Vibrating tables, vibrating compaction tables, and bulk bag unloaders for the optimization of indust

Efficiency and accuracy are critical in the field of industrial engineering. Businesses depend on cutting-edge gear and equipment to ensure efficient operations and the best outcomes. These cutting-edge instruments are essential for raising production, increasing material handling, and streamlining several industrial processes.

Compaction Using Vibrating Tables: Vibrating tables are versatile machinery that consolidates and settles materials controllably. Using vibrations, they densify and compress materials like powders, granules, and bulk solids. Vibrating tables are utilized extensively in several sectors, including construction, pharmaceuticals, food processing, and others. These tables are especially useful when it is necessary to distribute bulk materials properly, fill molds without air spaces, or securely pack particles for shipment. Vibrating table increase product quality, reduce waste, and guarantee consistency by exposing the materials to regulated vibrations.

Achieving Uniform Density using Vibrating Compaction Tables: Vibrating compaction table is the next step in compacting materials. With these specialized tables, bulk materials may be compacted, resulting in a consistent density, and removing gaps or air pockets. They are often used in the concrete and building sectors to cast concrete pavers, blocks, and other precast elements. The material is subjected to high-frequency vibrations on the vibrating compaction tables, which cause it to settle and develop a thick, homogenous structure. This procedure reduces the possibility of errors and enhances the end product’s strength and durability.

Using Bulk Bag Unloaders to Transfer Materials Effectively: The effective unloading of bulk bags is essential for enterprises dealing with significant amounts of bulk commodities, such as powders, grains, or chemicals. Bulk bag unloaders streamline the procedure, enabling smooth material transfer while reducing human labor requirements and hazards of contamination. Bulk Bag Unloaders have a conveyor or feeding mechanism, integrated vibration technology, and a framework with movable hooks to fasten the bulk bag. The vibrating movement helps to manage the flow of materials out of the bag and into subsequent operations, including mixers, hoppers, or packaging systems. Manufacturers may improve flow rate and avoid material blockage or bridging by controlling vibration intensity.

Utilizations and Advantages: There are many diverse industrial uses for vibrating tables, vibrating compaction tables, and bulk bag unloaders. Vibrating compaction tables help produce high-quality concrete blocks for the building industry, while vibrating tables support melding and casting operations. This equipment is used by pharmaceutical businesses to combine powders and condensed tablets, resulting in consistently high-quality products. Vibrating tables in the food sector provide effective packing by settling and densifying granular or powdered items. They boost product quality, increase operational effectiveness, and optimize material handling operations. Manufacturers may save money and improve their competitiveness in the market by minimizing waste and faults. By reducing physical labor and the risk of accidents from heavy lifting, these products also contribute to a safer working environment.

In industrial engineering, vibrating tables, compaction tables, and bulk bag unloaders have become essential instruments. Numerous industries have been transformed by their capacity to improve material handling, improve compaction, and enable effective material transfer. Businesses may obtain consistent outcomes, reduce waste, and boost productivity by using the power of vibrations. These instruments will improve as technology develops further, providing even more accuracy and efficiency in industrial operations.

Importance of Rectangular and Circular vibrating screen

Screening medium to coarse-grained bulk materials (5.0 mm to 100 mm) is done by circular vibrating screens, also known as Circular vibrating screen. For circular vibrating screens to function, the screen mesh is indirectly excited. Unbalanced masses cause a circular vibrating motion in the entire screen frame.

Rectangular Vibrating Screen Characteristics

Rectangular vibrating screen come in various models and configurations to meet virtually every screening, dewatering, classification, or scalping need.

Stainless steel mesh, nylon or synthetic fabric, bar screen, or wedge wire dewatering panels are some other materials found in screens.

Screen fabric is chosen for longer durability and is set up for easy maintenance and replacement. Carbon steel, corrosion-resistant stainless steel, or another lined media can be used for Vibrating compaction table contact surfaces, depending on the quality of the screened bulk material.

Screen bodies can either be open, exposing the processed material or closed, preventing dust from escaping.

A cassette of bouncing balls can be arranged to lessen screen cloth choking caused by sticky materials.

Screeners that are either round or mechanical, or rectangular:

One of the three most common screener shapes is a rectangular shape. These machines are a great all-around option compared to circular screeners, which are more space-efficient but usually more expensive, and mechanical screeners, which are easier to use but less successful at fine-separating and sieving chores.

When deciding on a screener, it's important to think about the following:

Needs in Manufacturing:

A good screener consistently and successfully separates or screens out the target material. To maximize productivity, you should invest in machines that can perform many functions.

Footprint:

A compact machine has many advantages in crowded manufacturing facilities. However, smaller devices are limited in the material they can process simultaneously. A machine with a larger footprint could be preferable if production volumes are high.

Maintenance:

Most screeners need help to function properly during maintenance, reducing your efficiency. If downtime is not an option, a machine with easily accessible parts and minimal moving parts may be the best buy.

Safety:

Pharmaceutical and chemical manufacturing are only two examples of industries where screening for safety is a top priority. You can install ventilation hoods on many screeners to keep your team safe when working with potentially dangerous chemicals.

How to Use a Rectangular Vibrating Screen:

The screen frame vibrates straight or linearly because the motors are mounted at right angles. Because of this, larger particles are efficiently conveyed forward even when the screen's frame is tilted upward. The structure of the rectangular screen can be tilted downward at an angle that best suits the intended use. The machine's capacity is maximized in the uphill position, leading to a pool at the feed end. The water pressure in the pool causes the fluid to spread more. The large particles are efficiently transported by the screen frame's horizontal Vibrating table screens and released outside the pool area.

Conclusion:

Buying powder materials in bulk can save businesses a lot of money and boost output at powder processing facilities. However, powder processing companies must invest in a bulk bag unloader system to collect the product and dispense it into the processing line to take advantage of all this and more.